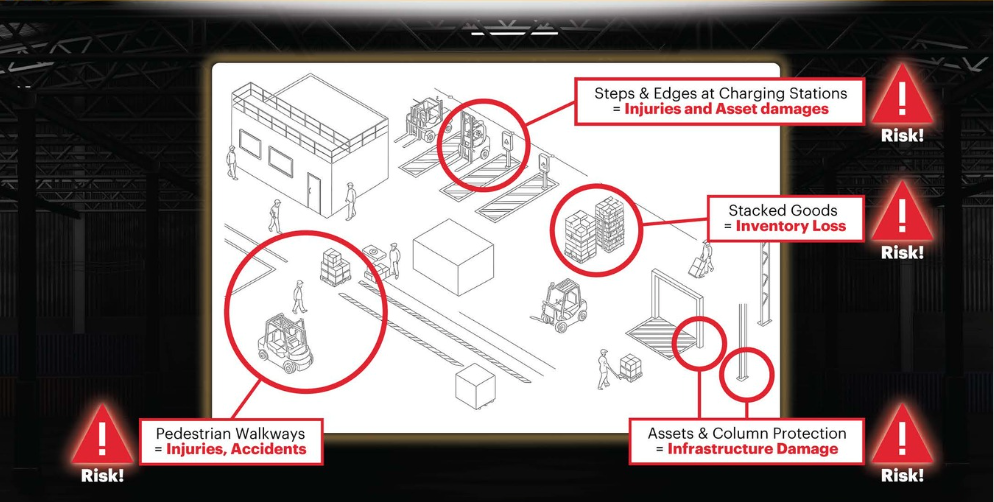

Where Damage Causes the Most Downtime

The same impact zones appear in almost every facility

This Is Why It Keeps Happening

..and why traditional protection fails in live environments

-

Vehicle traffic patterns are fixed — impacts repeat in the same locations

-

Steel barriers transfer force instead of absorbing it

-

Repairs happen after damage, not before

-

Most sites react to incidents instead of engineering them out

If any of this sounds familiar, your site already has predictable damage risk

-

Forklifts share space with pedestrians

-

Aisles narrow near machinery or racking

-

Temporary repairs are common

-

Columns or racks show visible impact marks

-

Incidents are handled locally, not systematically

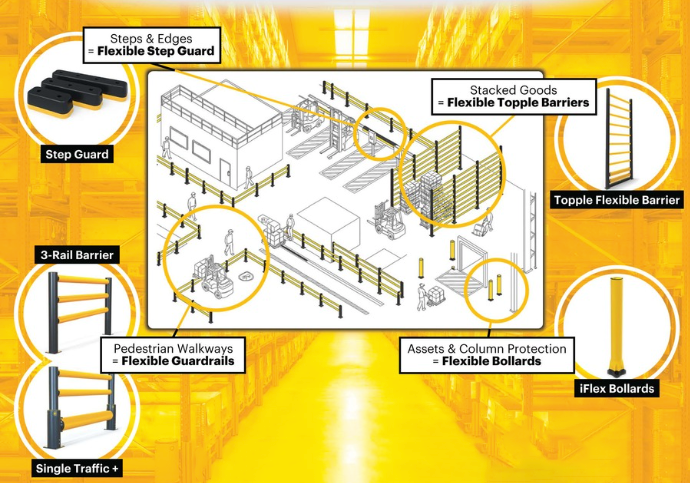

GOOD NEWS! Damage can be engineered out — before it stops operations

Most facilities already know where impacts happen. The challenge is moving from reactive repairs to engineered prevention.

This is WHY A-SAFE invented the first polymer barrier 40 years ago.

DISCOVER OUR DEDICATED DAMAGE & DOWNTIME SAFETY GUIDE

Click Here to receive your DOWNTIME AND DAMAGE SAFETY GUIDE!

Absorb the impact. Return to shape. Keep operations moving.

In live facilities, impacts are unavoidable. What matters is how protection responds when they occur.

Advanced polymer protection is engineered to:

-

Flex on impact to absorb energy

-

Return to shape after contact

-

Protect assets without transferring damage

-

Remain in service after repeated strikes

The result is fewer repairs, less downtime, and sustained operational uptime.

Keeping Your Assets Safe From Damage

Why Consider Polymer Protection?

Contact our safety experts today for your free, no-obligation consultation