PIONEERING WORKPLACE SAFETY

Rendi i tuoi luoghi di lavoro più sicuri

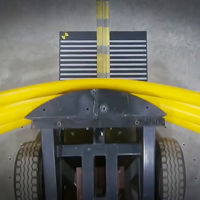

Protezioni per pedoni

Le protezioni antiurto pedonali A-SAFE permettono di ridurre il rischio di incidenti e di aumentare il livello di sicurezza per il personale.

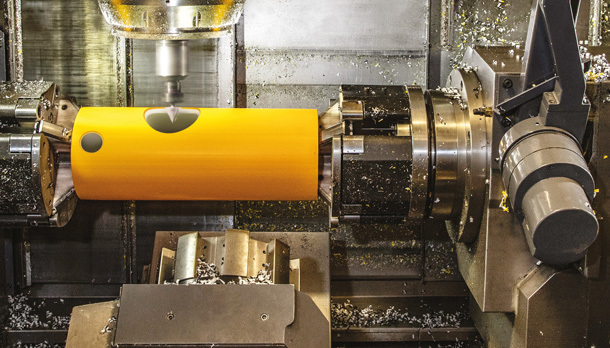

Minori costi operativi

Riduci i costi di manutenzione, riparazioni, sostituzioni e tempi di fermo grazie alle nostre barriere elastiche che non si corrodono, non arrugginiscono o sbiadiscono e non hanno necessità di essere riverniciate.

Protezioni antiurto testate e certificate

Le nostre barriere di sicurezza vengono testate e certificate in modo indipendente da enti certificatori riconosciuti globalmente in modo da poter essere certi delle prestazioni dei nostri prodotti.

A-SAFE Tour virtuale

Contatta oggi i nostri esperti di sicurezza per una consulenza gratuita e senza impegno

Trova la protezione antiurto adatta alle tue necessità

Le più grandi aziende del mondo hanno scelto le nostre protezioni

Leggi i nostri case study e scopri perchè i più grandi marchi e gli stabilimenti industriali più trafficati si affidano ai prodotti A-SAFE per garantire la sicurezza del personale, la protezione delle risorse e l'efficienza dei luoghi di lavoro.

Case Study

Le barriere A-SAFE sono le più testate al mondo, guardale in azione!

Guarda tutti i nostri testBarriere di sicurezza testate e certificate

Le barriere A-SAFE sono le più testate al mondo. Le nostre strutture di prova sono certificate in modo indipendente dall'ente di certificazione TÜV Nord.

Contatta oggi i nostri esperti di sicurezza per una consulenza gratuita e senza impegno

Perchè scegliere A-SAFE?

Scopri A-SAFE

Contatta oggi i nostri esperti di sicurezza per una consulenza gratuita e senza impegno

Contatta oggi i nostri esperti di sicurezza per una consulenza gratuita e senza impegno

Contact our safety experts today for your free, no-obligation consultation

)

)

)

)

)

)

)

)

)

)

)