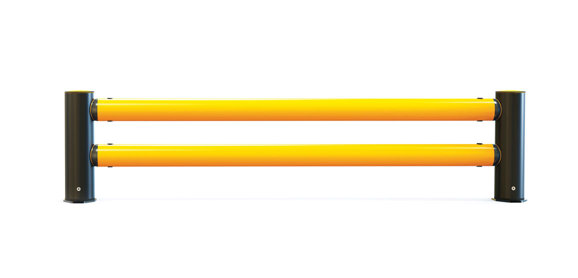

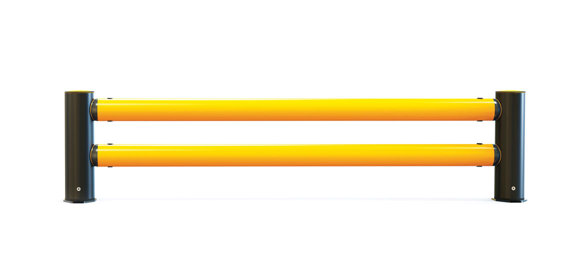

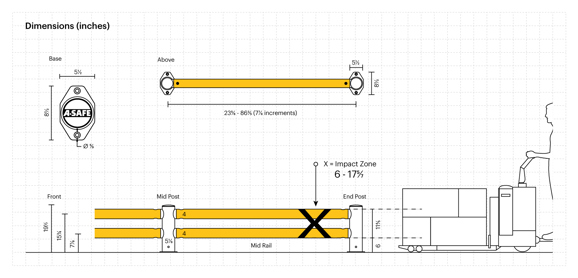

mFlex Double Traffic Guardrail

mFlex™ Double Traffic Guardrail is designed to safeguard walls, structures, goods and machinery from lightweight hand operated equipment and powered pallet trucks.

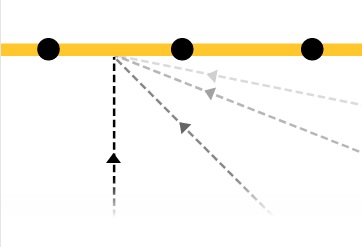

Double rails increases the height and strength of the impact zone, providing greater impact resistance and improving protection against general wear and tear. Over time, frequent impacts can damage surfaces, materials and stock. It can even break expensive equipment.